Products Categories

Feature Products

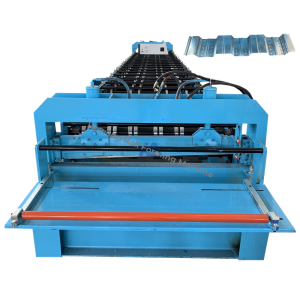

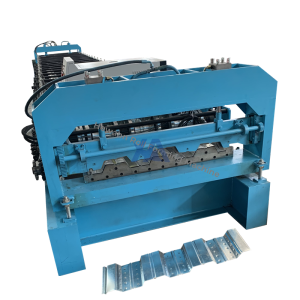

Metal Floor Decking Forming Equipment Floor Deck Roll Forming Machine

Metal Floor Decking Forming Equipment & Floor Deck Roll Forming Machine by Howann. PLC controlled, 15-30m/min speed, handles 1-1.5mm thickness. Produces high-quality floor decks for construction.

Machine Video

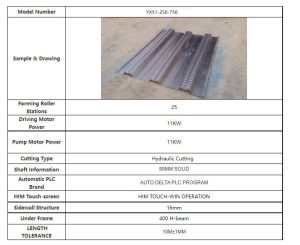

Machine Specification

|

Suitable material

|

PPGI GI AL

|

|

Coil Width

|

914/925/1000/1200/1220/1250mm as custom

|

|

Thickness

|

1-1.5mm as custom

|

|

Power

|

380V 50Hz 3Phase as custom

|

|

Main motor

|

11+11KW Siemens

|

|

Hydraulic motor

|

7.5KW Siemens

|

|

Speed

|

15-30m/min

|

|

Forming stations

|

22-28 rows

|

|

Roller material

|

Cr12 steel with vacuum heat treatment HRC57°-60°

|

|

Shaft material

|

45# steel quenched and tempered

|

|

Shaft diameter

|

90mm

|

|

Chain

|

1.2 inch

|

|

Screem HMI

|

Delta , Touch Screen

|

|

PLC

|

Delta , Siemens

|

|

Processing precision

|

Within 1mm

|

|

Size

|

11.6m×1.5m×1.2m

|

|

Weight

|

9.5T

|

Machine Features

1. Stable performance: steel plate uncoiler, uniform feeding speed and high stability;

2. Work: hydraulic synchronization and hydraulic punching system, to improve work efficiency, precision and quality of finished products;

3. The quality of the finished product is good: the floor deck produced by it is light in weight, high in load bearing and good in performance;

4. Simple construction and convenient assembly;

5. To replace the traditional formwork and the shortcomings of the traditional formwork, it can be used as part of the structural strength to reduce material costs;

6. It is easy to construct reinforcement, wiring and piping;

7. The appearance is neat and beautiful.

Packaging Type Of Bag

Machine Function

Machine Option

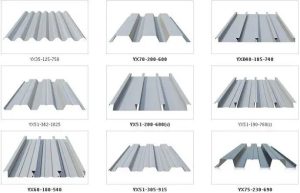

The Metal Floor Decking Forming Equipment offers comprehensive customization options to meet diverse production requirements. Customers can select from various coil widths including 914mm, 925mm, 1000mm, 1200mm, 1220mm, and 1250mm to accommodate specific project specifications.

Material thickness can be customized between 1.0mm to 1.5mm based on application needs, processing PPGI, GI, and aluminum materials. The machine speed is adjustable from 15-30 meters per minute, allowing optimization for different production volumes.

For control systems, options include Delta or Siemens PLC with touch screen HMI interface in multiple languages. The forming stations can be configured with 22 to 28 rows depending on the complexity of the deck profile required.

Additional customization includes roller materials (Cr12 steel with vacuum heat treatment), shaft specifications (45# steel quenched and tempered), and power configurations (380V 3-phase).

Howann provides tailored solutions for specific application requirements, ensuring optimal performance for each customer’s unique production needs. All components are designed for long service life and minimal maintenance, with technical support available for installation and operational training.

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.